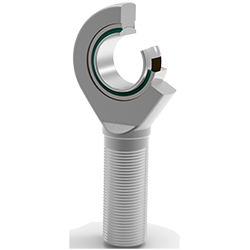

产品编号:SA…C 5~30 SA…ETL-2RS 15~80

滑动磨擦副:SA…C 钢/PTFE复合材料

SA…ETL-2RS 钢/PTFE编织物

产品特点:SA…C 自润滑组装杆端关节轴承是由杆端体和自润滑向心关节轴承GE…C组装而成,杆端体材料是碳钢,表面镀锌;无需润滑。

SA…ETL-2RS 自润滑组装杆端关节轴承是由杆端体和自润滑向心关节轴承GE…ET-2RS组装而成,杆端体材料是碳钢,表面镀锌;无需润滑。

使用温度范围:SA…C -50℃~+150℃

SA…ETL-2RS -30℃~+130℃

轴 承 型 号 Bearing number | 外 形 尺 寸 Dimensions mm | 额定载荷 Load ratings kN | 重量 Weight ≈kg | ||||||||||||

d | B | dk | C1 max | d2

| G 6g | h | l1 min | l2

| l7

| rs min | αº ≈ | 动载荷 Dynamic | 静载荷 Static | ||

SA5C | 5 | 6 | 10 | 4.5 | 21 | M5 | 36 | 16 | 46.5 | 11.5 | 0.3 | 13 | 3.6 | 3.9 | 0.015 |

SA6C | 6 | 6 | 10 | 4.5 | 21 | M6 | 36 | 16 | 46.5 | 11.5 | 0.3 | 13 | 3.6 | 5.5 | 0.016 |

SA8C | 8 | 8 | 13 | 6.5 | 24 | M8 | 42 | 21 | 54 | 13 | 0.3 | 15 | 5.8 | 10 | 0.026 |

SA10C | 10 | 9 | 16 | 7.5 | 29 | M10 | 48 | 26 | 62.5 | 15.5 | 0.3 | 12 | 8.6 | 16 | 0.050 |

SA12C | 12 | 10 | 18 | 8.5 | 34 | M12 | 54 | 28 | 71 | 18 | 0.3 | 10 | 11 | 23 | 0.068 |

SA15C | 15 | 12 | 22 | 10.5 | 40 | M14 | 63 | 34 | 83 | 21 | 0.3 | 8 | 18 | 32 | 0.120 |

SA15ETL-2RS | 25 | ||||||||||||||

SA17C | 17 | 14 | 25 | 11.5 | 46 | M16 | 69 | 36 | 92 | 24 | 0.3 | 10 | 22 | 44 | 0.190 |

SA17ETL-2RS | 32 | ||||||||||||||

SA20C | 20 | 16 | 29 | 13.5 | 53 | M20×1.5 | 78 | 43 | 104.5 | 25.5 | 0.3 | 9 | 31 | 60 | 0.300 |

SA20ETL-2RS | 45 | ||||||||||||||

SA25C | 25 | 20 | 35.5 | 18 | 64 | M24×2 | 94 | 53 | 126 | 31 | 0.6 | 7 | 51 | 85 | 0.555 |

SA25ETL-2RS | 85 | ||||||||||||||

SA30C | 30 | 22 | 40.7 | 20 | 73 | M30×2 | 110 | 65 | 146.5 | 35.5 | 0.6 | 6 | 65 | 110 | 0.875 |

SA30ETL-2RS | 110 | ||||||||||||||

SA35ETL-2RS | 35 | 25 | 47 | 22 | 82 | M36×3 | 140 | 82 | 181 | 41 | 0.6 | 6 | 140 | 146 | 1.42 |

SA40ETL-2RS | 40 | 28 | 53 | 24 | 92 | M39×3 | 150 | 86 | 196 | 47 | 0.6 | 7 | 175 | 180 | 1.85 |

SAS40ETL-2RS | 40 | 28 | 53 | 23 | 92 | M42×3 | 145 | 86 | 191 | 47 | 0.6 | 7 | 99 | 180 | 2.04 |

SA45ETL-2RS | 45 | 32 | 60 | 28 | 102 | M42×3 | 163 | 92 | 214 | 52 | 0.6 | 7 | 225 | 240 | 2.49 |

SAS45ETL-2RS | 45 | 32 | 60 | 27 | 102 | M45×3 | 165 | 95 | 216 | 52 | 0.6 | 7 | 127 | 240 | 2.74 |

SA50ETL-2RS | 50 | 35 | 66 | 31 | 112 | M45×3 | 185 | 104 | 241 | 60 | 0.6 | 6 | 275 | 290 | 3.58 |

SAS50ETL-2RS | 50 | 35 | 66 | 30 | 112 | M52×3 | 195 | 110 | 251 | 60 | 0.6 | 6 | 156 | 290 | 4.07 |

SA60ETL-2RS | 60 | 44 | 80 | 39 | 135 | M52×3 | 210 | 115 | 277.5 | 75.5 | 1.0 | 6 | 430 | 450 | 5.89 |

SAS60ETL-2RS | 60 | 44 | 80 | 38 | 135 | M60×4 | 225 | 120 | 292.5 | 75.5 | 1.0 | 6 | 245 | 450 | 6.79 |

SA70ETL-2RS | 70 | 49 | 92 | 43 | 160 | M56×4 | 235 | 125 | 315 | 95 | 1.0 | 6 | 550 | 610 | 8.51 |

SAS70ETL-2RS | 70 | 59 | 92 | 42 | 160 | M72×4 | 265 | 132 | 345 | 95 | 1.0 | 6 | 313 | 610 | 11.2 |

SA80ETL-2RS | 80 | 55 | 105 | 48 | 180 | M64×4 | 270 | 140 | 360 | 105.5 | 1.0 | 6 | 705 | 750 | 12.3 |

SAS80ETL-2RS | 80 | 55 | 105 | 47 | 180 | M80×4 | 295 | 147 | 385 | 105.5 | 1.0 | 6 | 400 | 750 | 15.3 |

可提供不同螺距或螺纹精度有特殊要求的杆端关节轴承。

若是左旋螺纹,轴承型号和螺纹标记需加“L”和“左”,例如:SAL20C M20×1.5左-6g。