产品编号:SIZP…S 4.83~25.4

滑动磨擦副:钢/青铜

产品特点:镶垫杆端关节轴承杆端体材料是碳钢,表面镀锌,滑动表面镶入青铜衬垫;内圈材料是轴承钢,淬火,球面镀硬铬,除了孔径小于6.35外,其余均可通过油杯润滑。

使用温度范围:-50℃~+150℃

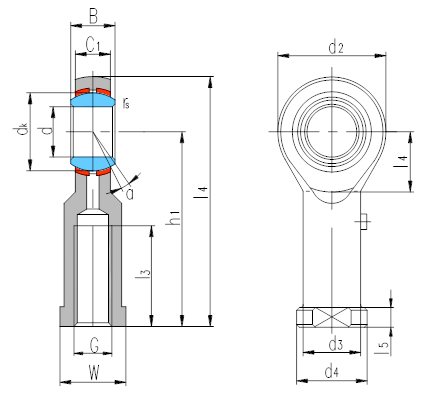

轴 承 型 号 Bearing number | 外 形 尺 寸 Dimensions mm/inch | 额定载荷 Load ratings kN | 重量 Weight ≈kg | ||||||||||||||||

d | B | dK | C1 max | d2

| G UNF-2B | h1 | l3 min | l4

| l5

| l7 | W | d3

| d4

| rs min | α˚ ≈ | 动载荷 Dynamic | 静载荷 Static | ||

SIZP4S1) | 4.83 | 7.92 | 11.1 | 6.35 | 15.88 | 10-32 | 26.97 | 14.27 | 34.93 | 4.75 | 9 | 7.92 | 7.54 | 10.31 | 0.3 | 10 | 3.4 | 4.6 | 0.015 |

0.19 | 0.312 | 0.437 | 0.25 | 0.625 | 1.062 | 0.562 | 1.375 | 0.187 | 0.354 | 0.312 | 0.297 | 0.406 | 0.012 | ||||||

SIZP6S1) | 6.35 | 9.53 | 12.7 | 7.14 | 19.05 | 1/4-28 | 33.32 | 19.05 | 42.85 | 4.75 | 10.5 | 9.53 | 9.15 | 11.91 | 0.3 | 13 | 4.5 | 7.7 | 0.025 |

0.25 | 0.375 | 0.5 | 0.281 | 0.75 | 1.312 | 0.75 | 1.687 | 0.187 | 0.413 | 0.375 | 0.36 | 0.469 | 0.012 | ||||||

SIZP7S | 7.94 | 11.10 | 15.88 | 8.74 | 22.23 | 5/16-24 | 34.93 | 19.05 | 46.02 | 4.75 | 11.7 | 11.1 | 10.72 | 12.70 | 0.3 | 10 | 6.9 | 8.4 | 0.036 |

0.3125 | 0.437 | 0.625 | 0.344 | 0.875 | 1.375 | 0.75 | 1.812 | 0.187 | 0.461 | 0.437 | 0.422 | 0.5 | 0.012 | ||||||

SIZP9S | 9.53 | 12.70 | 18.26 | 10.31 | 25.40 | 3/8-24 | 41.28 | 23.80 | 53.98 | 6.35 | 12.3 | 14.27 | 13.89 | 17.45 | 0.6 | 9 | 9.4 | 10 | 0.061 |

0.375 | 0.5 | 0.719 | 0.406 | 1 | 1.625 | 0.937 | 2.125 | 0.25 | 0.484 | 0.562 | 0.547 | 0.687 | 0.024 | ||||||

SIZP11S | 11.11 | 14.27 | 20.62 | 11.1 | 28.58 | 7/16-20 | 46.02 | 26.97 | 60.33 | 6.35 | 14 | 15.88 | 15.49 | 19.05 | 0.6 | 11 | 11 | 13 | 0.081 |

0.4375 | 0.562 | 0.812 | 0.437 | 1.125 | 1.812 | 1.062 | 2.375 | 0.25 | 0.551 | 0.625 | 0.61 | 0.75 | 0.024 | ||||||

SIZP12S | 12.7 | 15.88 | 23.81 | 12.7 | 33.32 | 1/2-20 | 53.98 | 30.15 | 70.64 | 6.35 | 16.2 | 19.05 | 18.67 | 22.23 | 0.6 | 9 | 15 | 19 | 0.133 |

0.5 | 0.625 | 0.937 | 0.5 | 1.312 | 2.125 | 1.187 | 2.781 | 0.25 | 0.638 | 0.75 | 0.735 | 0.875 | 0.024 | ||||||

SIZP15S | 15.88 | 19.05 | 28.58 | 14.27 | 38.10 | 5/8-18 | 63.50 | 38.10 | 82.55 | 7.92 | 18.2 | 22.23 | 21.84 | 25.40 | 0.6 | 11 | 20 | 21 | 0.190 |

0.625 | 0.75 | 1.125 | 0.562 | 1.5 | 2.5 | 1.5 | 3.25 | 0.312 | 0.717 | 0.875 | 0.86 | 1 | 0.024 | ||||||

SIZP19S | 19.05 | 22.23 | 33.32 | 17.45 | 44.45 | 3/4-16 | 73.03 | 44.45 | 95.25 | 7.92 | 20.9 | 25.4 | 25.02 | 28.58 | 0.6 | 10 | 29 | 29 | 0.285 |

0.75 | 0.875 | 1.312 | 0.687 | 1.75 | 2.875 | 1.75 | 3.75 | 0.312 | 0.823 | 1 | 0.985 | 1.125 | 0.024 | ||||||

SIZP25S | 25.40 | 34.93 | 47.63 | 25.40 | 69.85 | 5/4-12 | 104.78 | 53.98 | 139.70 | 11.10 | 33.1 | 38.1 | 37.72 | 44.45 | 0.6 | 14 | 60 | 101 | 1.00 |

1 | 1.375 | 1.875 | 1 | 2.75 | 4.125 | 2.125 | 5.5 | 0.437 | 1.303 | 1.5 | 1.485 | 1.75 | 0.024 | ||||||

1)不能润滑。

可提供不同螺纹精度要求的杆端关节轴承。

若是左旋螺纹,轴承型号和螺纹标记需加“L”和“LH”,例如:SILZP12S 1/2-20UNF-2BLH。

以上产品的杆端体和内圈可用不锈钢制造,轴承型号后面加“X”标识,即SIZP…S/X。